OX-W

Hard Anodizing

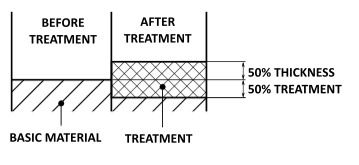

OX-W is a special aluminium hard anodizing treatment in compliance with MIL-A-8625 Type III, ISO 10074, and UNI 7796 standards.

Compared to conventional hard anodizing treatments, the OX-W treatment was developed to increase the characteristics of hard anodizing and obtain a more compact and uniform aluminium oxide film, with lower surface roughness and higher corrosion resistance.

It allows the achievement of high salt spray corrosion resistance with reduced anodizing thicknesses and on hard-to-process alloys such as series 2000 alloys and high-silicon content casting alloys.

It is also employed to treat parts for gas distribution and control (natural gas, hydrogen, and oxygen), in which properties of low surface roughness and high scratch and wear resistance are required.

Technical datasheet

Technical datasheet