Busbar is the technical term for the connecting bars between points in an electrical transfer or distribution circuit, normally of high power.

They are usually flat copper or aluminium bars, which are the two commonly used metals with a high specific electrical conductivity. In addition to the common industry where copper and aluminium busbars are used as connections for processes that require high current distribution, there has recently been a strong increase in the use of busbars for all connection systems between components in electric vehicles BEV and PHEV.

Copper, which is widely used to conduct electric current, requires a smaller cross-sectional area than aluminium due to its higher conductivity or specific conductivity.

Aluminum has different, special characteristics and advantages that may make it superior to copper in some applications:

- LIGHTNESS: Significant weight savings can be achieved. At the same capacity, the weight of aluminium is 50% of the weight of copper.

- CHEAPNESS: aluminium , due to its abundance and ease of extraction, has a very low cost and is certainly always lower than copper. The lower cost, about 1/3 of that of copper, combined with the weight of 1/2 to obtain the same capacity as an electrical conductor, brings the cost-effectiveness of an aluminium object to the value of 1/6 compared to the same object in copper.

- WORKABILITY: can be worked with all common machining techniques more easily than most other metals.

- VERSATILITY: alloys can be rigid or elastic, particularly strong or corrosion-resistant

- RECYCLABLE: easily recyclable with low costs.

- MECHANICAL STRENGTH: aluminium alloys offer a range of mechanical strengths from 60 to 530 N/mm2.

- ATOXIC: its salts are completely non-toxic

- DOES NOT GENERATE SPARKS: unlike ferrous metals, aluminium does not generate sparks when rubbed with other metals, which is why it is preferred in the flammable and explosive sectors.

Electroless nickel plating produces a nickel-phosphorus alloy layer with numerous advantages for application on aluminium :

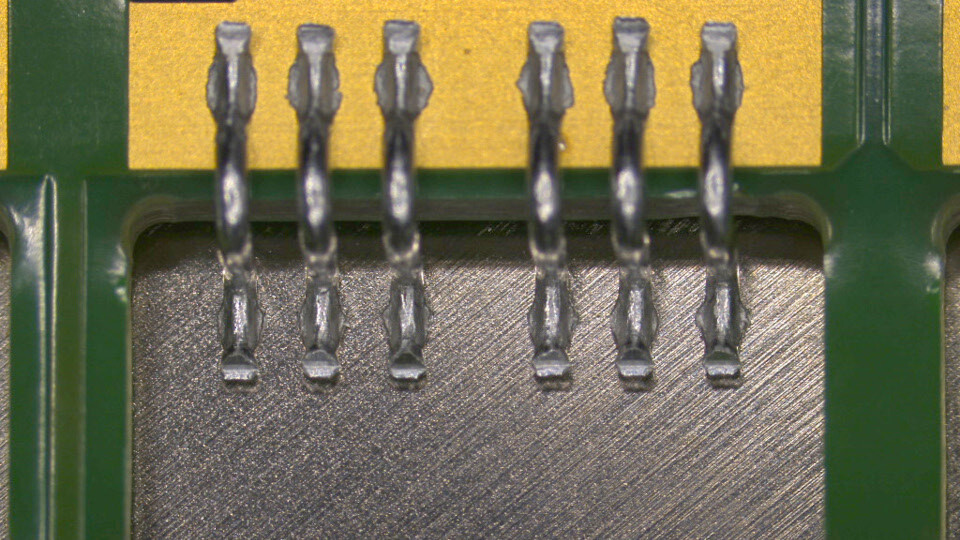

- SOLDERABILITY: Electroless nickel has good welding performance and elements can be welded to it using the main techniques, including ultrasonic welding.

- CORROSION RESISTANCE: the coating is compact and the corrosion resistance is far better than galvanic (electrolytic) nickel. The resistance to corrosion is of course proportional to the thickness of the coating.

- STAINLESS: electroless nickel protects the base metal from oxidation, but the great advantage is that the surface of electroless nickel is stainless to most corrosive agents and this results in the maintenance of surface electrical conductivity in screwed and unsoldered contacts. Copper and aluminium , when used bare, suffer from a progressive increase in contact resistance caused by the accumulation of oxidation products at the interface of the two surfaces.

- ADHESION: electroless nickel has high adhesion to aluminium alloys, much more than electrolytic nickel plating.

- UNIFORMITY: the coating thickness is very uniform without edge effect. It is therefore also ideal for parts with complicated shapes, cavities and deep holes.

- CONTROLLED THICKNESS: the thickness of the electroless nickel layer can be calibrated, depending on requirements, to values of a few microns as well as tens of microns with very tight tolerances.

- AESTHETICS: the coating has a shiny or semi-glossy appearance and the surface roughness exactly replicates that of the base material.

- HARDNESS: the hardness of the electroless nickel plating layer is high, always above 500 HV and can be increased by heat treatment. The wear resistance is very high.

Micron has developed an electroless nickel coating called NIPLATE® 500 which, in addition to having excellent corrosion resistance, adhesion and hardness characteristics, allows excellent solderability of electronic components using a variety of techniques, even the most special ones such as ultrasound and laser.

Our coating NIPLATE® 500 is already being used for the production of hundreds of thousands of busbars per year onto which ultrasonic welding is applied.